In the modern world of manufacturing, precision defines performance. Whether producing medical components, aerospace parts, or high-performance golf equipment, accuracy in machining determines the final product’s quality and function. When it comes to golf stick sole production, achieving the right tolerances through CNC machining is crucial. This is where the insights from the CNC part tolerances guide prove invaluable for both designers and manufacturers aiming to create consistent, high-quality results.

Understanding CNC Part Tolerances

CNC part tolerances refer to the allowable variations in a machined part’s dimensions. Even the most advanced CNC machines work within specific tolerance limits. In industries where precision dictates performance—like sports equipment manufacturing—these tolerances directly affect the feel, balance, and performance of the final product.

For example, in golf club design, every millimeter can alter swing weight or impact angle. A tighter tolerance ensures that each golf stick sole produced performs identically, maintaining consistent feedback for professional and amateur players alike.

Why Tolerances Matter in Golf Stick Sole Manufacturing

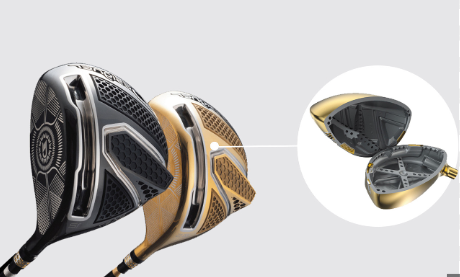

Golf clubs are not just sports tools; they are engineered products designed for maximum performance. The sole of the golf stick—its base that interacts with the ground—must be machined with high precision to achieve consistent ball contact and turf interaction.

Even the slightest deviation in thickness or curvature can cause differences in playability. CNC machining ensures these variations are minimized, making every sole uniform in design and weight. By applying the tolerance principles discussed in the CNC part tolerances guide, manufacturers can achieve precise repeatability, leading to enhanced performance and durability.

CNC Machining: The Backbone of Precision

CNC (Computer Numerical Control) machining allows manufacturers to produce intricate and high-tolerance components efficiently. When creating golf stick soles, materials like stainless steel, titanium, and carbon fiber composites are often used. CNC machining ensures that these materials are shaped with micron-level accuracy—far superior to traditional manual methods.

Modern CNC equipment also allows for the integration of advanced 3D modeling, enabling designers to simulate tolerance effects before actual production begins. This minimizes material waste and improves cost-efficiency, ensuring that the final product aligns perfectly with performance goals.

From Design to Production: Achieving Consistency

The process begins with CAD (Computer-Aided Design) models, where engineers define each feature of the golf stick sole, including dimensional tolerances. These tolerances are then applied during CNC programming, dictating the precision level of each cut, hole, and surface finish.

Through continuous inspection and feedback, the production process ensures consistency across multiple units. Manufacturers who implement the tolerance strategies outlined in the CNC part tolerances guide achieve near-perfect uniformity, setting new standards in sports engineering.

CNC Machining Beyond Sports: A Global Impact

While golf club manufacturing is an exciting application, the same precision principles extend to medical, aerospace, and automotive industries. For example, companies like Yicen Precision have demonstrated how tight tolerance control can drive innovation across multiple sectors, producing components that demand accuracy, durability, and reliability.

Conclusion

In today’s performance-driven market, CNC machining has become the cornerstone of precision manufacturing. From the swing of a golfer’s club to the operation of a medical device, every part depends on tolerances that define its perfection. Understanding these tolerances, as outlined in the CNC part tolerances guide, empowers designers and manufacturers to push the boundaries of quality and innovation.