Ensuring that packaging can endure pressure during transit and storage is vital for protecting products and maintaining brand reputation. The Box Compression Tester is a specialized laboratory instrument that evaluates the compressive strength of corrugated boxes and other packaging materials, offering a dependable way to test how much weight a box can bear before collapsing.

For businesses in packaging, manufacturing, logistics, and shipping, this device plays a crucial role in product safety and quality control.

What is a Box Compression Tester?

A Box Compression Tester (BCT) is used to measure the load-bearing capacity of boxes by simulating vertical pressure, such as the weight experienced during stacking in warehouses or transportation. The machine applies a controlled force to a test box and records the amount of pressure it can handle before deforming or failing.

This process helps packaging professionals determine whether a box is suitable for stacking and shipping, and it aids in designing boxes that are both durable and cost-effective.

Why Use a Box Compression Tester?

🔍 Ensure Structural Integrity

Knowing the maximum compressive force your box can handle ensures safer packaging and reduces the chances of in-transit product damage.

📦 Prevent Shipping Losses

Weakened or poorly tested boxes can collapse under pressure, leading to damaged goods and increased returns.

🌍 Meet Industry Standards

The test complies with key international protocols such as ASTM D642, TAPPI T804, and ISO 12048, helping businesses stay audit-ready.

💡 Optimize Packaging Materials

Reduce material costs by avoiding unnecessary overdesign—test to find the perfect balance between strength and efficiency.

✅ Improve Customer Satisfaction

Delivering undamaged goods enhances the customer experience and boosts brand reliability.

Main Features of a High-Quality Box Compression Tester

Modern BCT machines come equipped with features that improve accuracy, reliability, and ease of use:

-

Rugged Compression Plates – For even force distribution across the test surface

-

Digital or Touchscreen Controls – For precise force readings and easy operation

-

Variable Load Speed – Allows testing under different real-world conditions

-

Overload and Safety Lock Systems – Protect users and prevent equipment damage

-

Data Logging & PC Connectivity – Track results, generate reports, and analyze trends over time

How Compression Testing Works

-

The sample box is placed between two steel plates.

-

The top plate descends at a set speed to apply compressive force.

-

The test continues until the box deforms or collapses.

-

The machine records the maximum force the box withstands before failure.

This value indicates how many similar boxes can be safely stacked and transported without risk.

Who Benefits from a Box Compression Tester?

-

🏭 Packaging & Carton Manufacturers – Validate the strength of new box designs

-

🚚 Shipping & Logistics Companies – Reduce damage during transit

-

🛒 E-commerce Retailers – Ensure safe delivery of packaged goods

-

💊 Pharmaceutical Suppliers – Protect fragile and regulated items

-

🍴 Food & Beverage Brands – Maintain packaging performance during storage and transport

Conclusion

The Box Compression Testing is a vital tool for any company involved in packaging, warehousing, or transportation. It delivers critical insights into packaging performance and supports smarter, safer, and more sustainable product delivery.

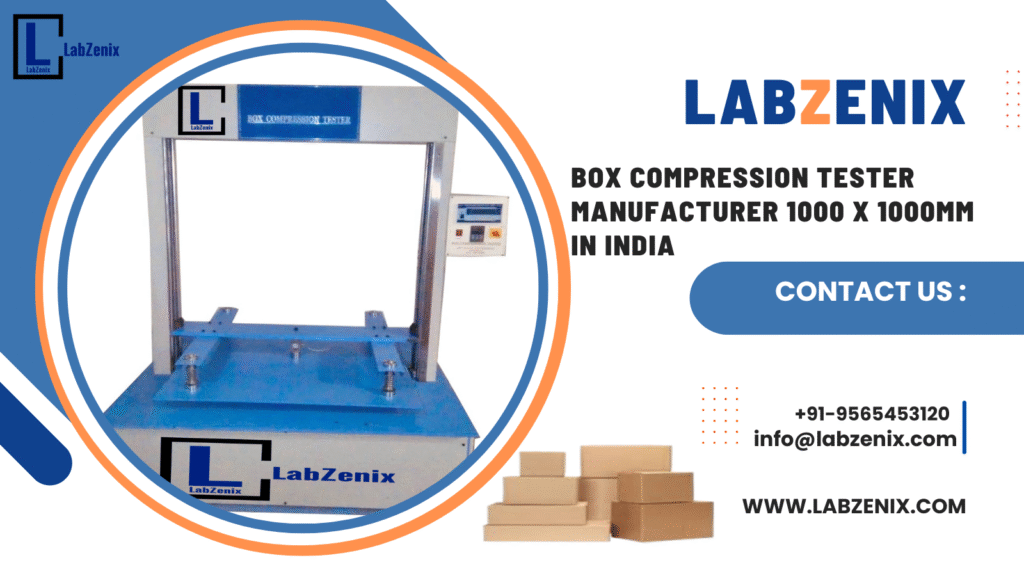

At LabZenix, we offer industry-standard Box Compression Testers engineered for precision and durability. Whether you’re testing small cartons or large shipping boxes, our solutions help you maintain top-tier packaging quality.