The Modern Sewage Crisis: Why Proper Treatment Matters

As industries expand and urban populations grow, managing sewage responsibly is no longer an option—it’s a necessity. Left untreated, sewage pollutes water bodies, harms ecosystems, and poses severe health risks. A reliable sewage treatment plant is essential for transforming harmful waste into safe, reusable water. But plants alone aren’t enough—industrial water treatment chemicals play a silent yet powerful role in driving this transformation.

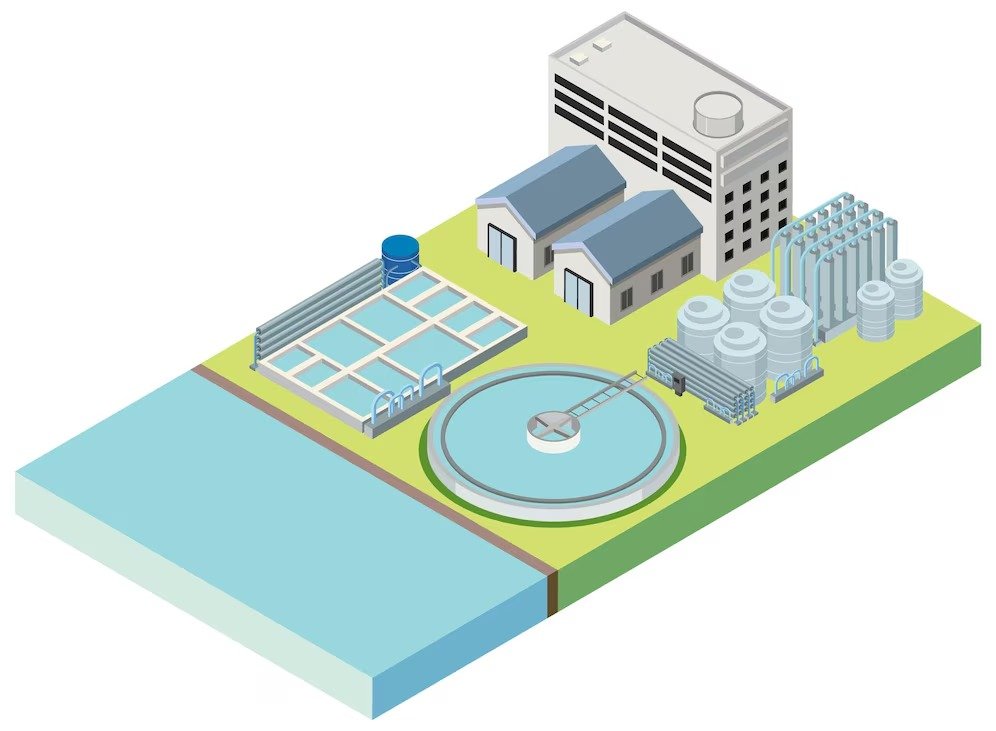

Understanding the Journey of Sewage to Clean Water

Sewage contains a mix of organic waste, chemicals, pathogens, and solids. The journey from dirty wastewater to reusable water happens in stages: preliminary, primary, secondary, and tertiary treatment. Each step uses a combination of mechanical processes and advanced chemical solutions to remove impurities. When done right, treated water meets environmental compliance and can be safely discharged or reused.

The Role of Industrial Water Treatment Chemicals

In the heart of every high-performing treatment plant lies a well-formulated mix of industrial water treatment chemicals. These chemicals break down contaminants, remove solids, neutralize toxins, and balance pH levels. From coagulants and flocculants to disinfectants and defoamers, they are engineered to work efficiently even under complex industrial waste conditions.

How Coagulants and Flocculants Enhance Treatment Efficiency

The first big challenge in sewage treatment is removing suspended particles. Coagulants destabilize these particles, while flocculants help them bind together and settle. Without these chemicals, particles would remain in the water, making it cloudy and dangerous. Using the right formula at the right dosage significantly boosts the efficiency of any sewage treatment plant.

Disinfection: The Final Barrier Against Pathogens

After solids and organic matter are removed, it’s time to kill the bacteria, viruses, and other pathogens. Disinfectants like chlorine, ozone, and UV-reactive chemicals ensure the water is safe. Among them, ozone stands out for its high oxidation potential and zero harmful residue—making it a top choice in many advanced industrial water treatment systems.

Tackling Odor and Sludge with Chemical Solutions

Unpleasant smells and thick sludge are two notorious byproducts of untreated sewage. Deodorizers and sludge conditioners make treatment more manageable and environmentally friendly. These specialized chemicals reduce hydrogen sulfide gas, improve sludge dewatering, and prevent corrosion in pipelines and tanks—protecting both the system and the environment.

Environmental Compliance and Cost Savings

Industries face strict discharge regulations. Failing to meet them can lead to fines or even shutdowns. Industrial water treatment chemicals help industries meet these standards consistently. More importantly, efficient treatment reduces the need for frequent maintenance, minimizes energy use, and cuts down on water procurement costs—delivering both ecological and economic benefits.

The Science Behind Customized Chemical Solutions

No two industries produce the same type of sewage. Textile, pharmaceutical, food processing, and chemical manufacturing all have unique effluent profiles. At Bisan Chemical Engineer, we understand the need for industry-specific solutions. Our custom-blended treatment chemicals are designed after a detailed analysis of wastewater composition, flow rate, and environmental goals.

Innovations Driving the Future of Sewage Management

The future of wastewater treatment lies in smart automation and eco-friendly chemicals. Advances like AI-based chemical dosing, biodegradable coagulants, and enzyme-based treatments are reshaping the landscape. Companies investing in these innovations not only stay compliant but also earn green certifications and improve brand value.

Why Choosing the Right Partner Changes Everything

Even the best sewage treatment plant won’t work efficiently without the right chemical partner. At Bisan Chemical Engineer, we combine technical expertise, lab testing, and on-site support to ensure seamless integration of our solutions. Our commitment to sustainability and innovation helps industries transform their wastewater challenges into opportunities.

Frequently Asked Questions (FAQ)

Q1. What is the main purpose of industrial water treatment chemicals?

Industrial water treatment chemicals are used to remove contaminants from wastewater, ensuring it is safe for discharge or reuse. They aid in coagulation, disinfection, odor control, and pH balancing.

Q2. Can these chemicals be harmful to the environment?

When used correctly, most modern treatment chemicals are eco-safe and comply with environmental standards. Advanced options like ozone and enzyme-based formulas offer sustainable alternatives.

Q3. Is chemical treatment enough for sewage management?

No. Chemical treatment is one part of a multi-step process. It works alongside mechanical and biological methods to ensure complete purification of sewage.

Q4. How do I choose the right treatment chemical for my industry?

The ideal chemical depends on the type of effluent your industry generates. It’s best to consult professionals like Bisan Chemical Engineer, who can analyze your wastewater and recommend the right solution.

Ready to Upgrade Your Sewage Treatment Process?

Wastewater doesn’t have to be a liability. With the right chemicals and guidance, it can become a valuable resource. Whether you’re running a new sewage treatment plant or looking to optimize an existing one, Bisan Chemical Engineer is your trusted partner in sustainable, efficient wastewater management.

Contact us today to schedule a consultation and take the first step toward cleaner operations and a greener tomorrow.