Monoethylene glycol (MEG) is a vital industrial chemical primarily used in the production of polyester fibers, polyethylene terephthalate (PET) resins, antifreeze, and coolants. Its versatile applications across various industries, including textiles, packaging, and automotive, make it a crucial component in global chemical markets. The growing demand for polyester fibers in the fashion industry and the rising use of PET bottles in food and beverage packaging are key drivers of the MEG market.

This guest post explores the current market size, key players, opportunities, challenges, demand drivers, and emerging trends shaping the monoethylene glycol industry.

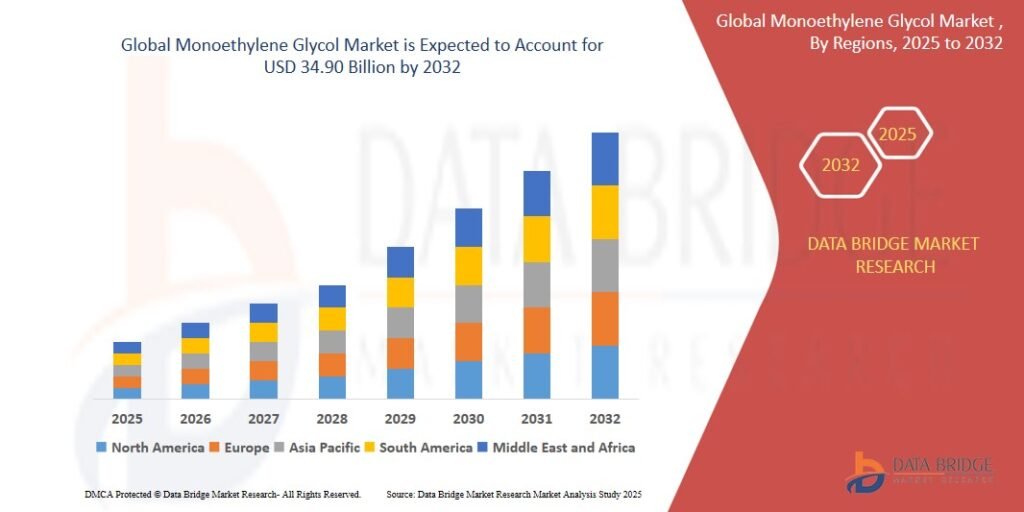

The global Monoethylene Glycol Market Size was valued at USD 26.22 billion in 2024 and expand to USD 34.90 billion by 2032, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period.

Explore emerging trends, key drivers, and market strategies in our in-depth Monoethylene Glycol Market analysis. Get the full report: https://www.databridgemarketresearch.com/reports/global-monoethylene-glycol-market

Market Size

The global monoethylene glycol market has witnessed steady growth in recent years, driven by increasing industrialization and urbanization. According to recent industry reports, the market was valued at approximately USD 27.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030, reaching USD 39 billion by the end of the decade.

Asia-Pacific dominates the MEG market, accounting for over 60% of global demand, with China being the largest consumer due to its booming textile and packaging industries. North America and Europe also hold significant shares, supported by strong demand from the automotive and construction sectors.

Market Share

The monoethylene glycol market is highly competitive, with key players focusing on capacity expansions and technological advancements to strengthen their positions. Some of the leading companies in the MEG market include:

-

SABIC (Saudi Arabia)

-

Sinopec (China)

-

Reliance Industries Ltd. (India)

-

Dow Chemical Company (U.S.)

-

Shell Chemicals (Netherlands)

-

ExxonMobil (U.S.)

-

Formosa Plastics Corporation (Taiwan)

These companies invest heavily in research and development to improve production efficiency and sustainability. Mergers, acquisitions, and partnerships are common strategies to expand market reach and enhance supply chain capabilities.

Market Opportunities and Challenges

Opportunities

-

Growing Demand for Polyester Fibers – The textile industry’s expansion, particularly in emerging economies, is boosting MEG consumption.

-

Rising PET Packaging Demand – Increased use of PET bottles in food, beverages, and pharmaceuticals is driving MEG demand.

-

Automotive Industry Growth – The need for antifreeze and coolants in electric and conventional vehicles presents new opportunities.

-

Bio-based MEG Development – Sustainable production methods using bio-ethylene glycol are gaining traction, offering eco-friendly alternatives.

Challenges

-

Volatile Raw Material Prices – Fluctuations in crude oil and naphtha prices impact MEG production costs.

-

Environmental Regulations – Strict environmental policies on plastic waste and emissions pose challenges for manufacturers.

-

Competition from Substitutes – Propylene glycol and other alternatives may limit MEG market growth in certain applications.

Market Demand

The demand for monoethylene glycol is primarily driven by:

-

Textile Industry – Polyester fibers, used in clothing and home textiles, account for the largest MEG consumption.

-

Packaging Sector – PET resins are widely used in bottles, films, and containers, increasing MEG demand.

-

Automotive Applications – Antifreeze and coolant formulations rely heavily on MEG for engine temperature regulation.

-

Construction Industry – MEG-based products are used in adhesives, coatings, and insulation materials.

Emerging economies like India, China, and Southeast Asian nations are witnessing rapid industrialization, further boosting MEG consumption.

Market Trends

Several key trends are shaping the future of the monoethylene glycol market:

-

Shift Towards Sustainable Production – Companies are investing in bio-based MEG to reduce carbon footprints.

-

Technological Advancements – Innovations in catalytic processes improve yield and reduce energy consumption.

-

Circular Economy Initiatives – Recycling PET waste into MEG is gaining momentum, supporting sustainability goals.

-

Strategic Expansions in Asia-Pacific – Major players are setting up new production facilities in high-growth regions.

-

Impact of Electric Vehicles (EVs) – While EVs reduce antifreeze demand, they still require thermal management solutions, sustaining MEG usage.

Conclusion

The monoethylene glycol market is poised for steady growth, supported by increasing demand from textiles, packaging, and automotive industries. While challenges like raw material price volatility and environmental regulations persist, opportunities in bio-based MEG and recycling present promising avenues for expansion.

Companies that invest in sustainable practices and technological innovations will likely lead the market in the coming years. As global industries evolve, MEG remains a critical chemical with diverse applications, ensuring its relevance in the future.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com