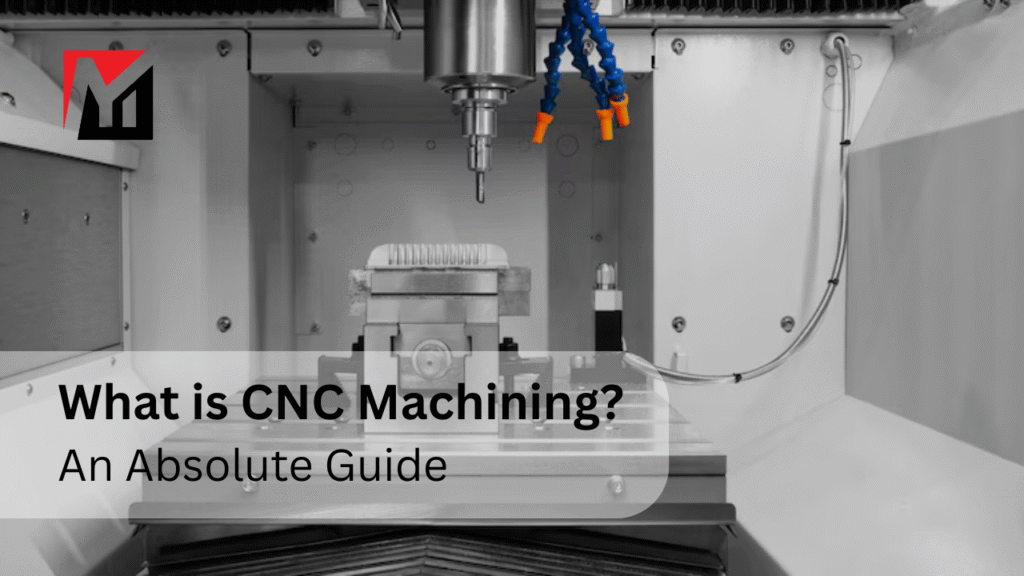

In the world of advanced manufacturing, precision and efficiency are critical. One technology that has revolutionized the production process is cnc machining. At MyT Machining, we specialize in providing top-tier CNC machining services tailored to meet the diverse needs of industries ranging from aerospace to medical devices. This comprehensive guide will walk you through everything you need to know about CNC machining—from its basic principles to its wide applications and benefits.

What Is CNC Machining?

CNC machining stands for Computer Numerical Control machining. It is an automated manufacturing process where pre-programmed computer software controls machinery tools to cut, shape, and finish materials into precise parts. Unlike manual machining, CNC machining offers unparalleled accuracy, consistency, and speed, making it the backbone of modern industrial production.

At MyT Machining, we leverage cutting-edge CNC technology to deliver products that meet the strictest quality standards and exacting client specifications.

How CNC Machining Works

The CNC machining process begins with a digital design created using CAD (Computer-Aided Design) software. This design is converted into a CAM (Computer-Aided Manufacturing) program, which generates the instructions for the CNC machine. These instructions direct the movement of cutting tools in multiple axes to remove material and create the desired shape.

CNC machines typically operate along three to five axes, allowing for complex geometries and high precision in parts manufacturing. The main types of CNC machining include milling, turning, drilling, and grinding.

Types of CNC Machining

CNC Milling

In CNC milling, rotating cutting tools remove material from a stationary workpiece to create complex shapes, grooves, and slots. This process is ideal for making flat surfaces, contours, and pockets.

CNC Turning

CNC turning involves rotating the workpiece while a stationary cutting tool shapes it. This method is widely used for producing cylindrical parts such as shafts and bushings.

CNC Drilling

CNC drilling machines produce holes with exact diameter and depth specifications. The process can be combined with milling or turning operations for multi-functional machining.

CNC Grinding

Grinding provides the final finishing touches to parts, achieving smooth surfaces and fine dimensional accuracy. It is often used for hardened materials and critical components.

Advantages of CNC Machining

Precision and Consistency

CNC machining delivers parts with micron-level precision, ensuring every component meets exact tolerances. This consistency is essential for industries where reliability is paramount.

Increased Productivity

Automated CNC processes reduce human error and increase throughput, enabling faster production runs without compromising quality.

Versatility

CNC machines can work on a wide range of materials, including metals, plastics, and composites. This versatility supports applications across automotive, aerospace, medical, and consumer goods sectors.

Cost Efficiency

While the initial programming of CNC machines requires investment, the ability to rapidly produce complex parts at scale lowers overall production costs, especially for medium to large runs.

Complex Geometries

CNC machining allows the creation of parts with intricate designs and fine details that are difficult or impossible to achieve through manual machining.

Materials Suitable for CNC Machining

At MyT Machining, we work with a broad spectrum of materials, selecting each based on the specific needs of the project:

-

Metals: Aluminum, stainless steel, titanium, brass, and nickel alloys.

-

Plastics: ABS, nylon, PEEK, Delrin, and polycarbonate.

-

Composites: Carbon fiber and fiberglass materials for lightweight, high-strength applications.

Each material requires careful consideration of cutting parameters, tooling, and machining strategy to optimize surface finish and dimensional accuracy.

Industries Benefiting from CNC Machining

Aerospace

High precision and durability are critical in aerospace parts. CNC machining produces complex components that meet stringent safety standards.

Automotive

From engine parts to custom accessories, CNC machining helps automotive manufacturers achieve tight tolerances and consistent quality.

Medical Devices

Surgical instruments, implants, and prosthetics demand biocompatible materials and high precision, which CNC machining reliably delivers.

Electronics

CNC machining produces enclosures, connectors, and intricate parts for electronics with high repeatability.

Oil and Gas

Machining durable components capable of withstanding harsh environments ensures reliability and safety in oilfield operations.

Why Choose MyT Machining for Your CNC Machining Needs?

At MyT Machining, we combine advanced CNC machinery with skilled engineers and quality assurance to deliver top-quality parts on time and within budget. Our commitment includes:

-

Customized Solutions: Tailored manufacturing processes designed to meet your unique specifications.

-

Rigorous Quality Control: Inspection at every stage to guarantee dimensional accuracy and surface finish.

-

On-Time Delivery: We understand deadlines and ensure timely completion of projects.

-

Competitive Pricing: Efficient workflows reduce waste and cost, passing savings on to you.

-

Comprehensive Support: From design consultation to post-production services, we provide full-cycle support.

The Future of CNC Machining

The industry is evolving with the integration of AI, automation, and IoT technologies, allowing for predictive maintenance, real-time monitoring, and further optimization of machining processes. These advancements promise higher productivity, lower costs, and enhanced part quality.

Conclusion

CNC machining is a transformative technology that drives modern manufacturing with precision, speed, and versatility. By partnering with a reliable CNC machining provider like MyT Machining, businesses can ensure superior quality parts that meet their demanding specifications and contribute to their competitive edge.

Explore the possibilities of CNC machining with MyT Machining and elevate your manufacturing capabilities to the next level.