You’re flipping through fabric swatches, dreaming up a new scarf or shirt, when the shopkeeper tosses out, “Spun or filament yarn?” You freeze, hand hovering over a soft cotton bolt. “Uh, what’s the difference?” you mumble, feeling like you missed a memo. Don’t worry—you’re not alone! Spun and filament yarns are the building blocks of textiles, each with its own vibe, from fuzzy warmth to silky smoothness. Knowing their differences can make or break your next project, whether you’re knitting a cozy blanket or designing a sleek dress. This blog breaks down spun and filament yarns, comparing their textures, strengths, and uses, with a nod to Pakistan’s thriving textile scene. Whether you’re a crafter or scouting yarn suppliers in Pakistan, let’s unravel the yarn mystery and find the right fit for you!

What Are Spun Yarns?

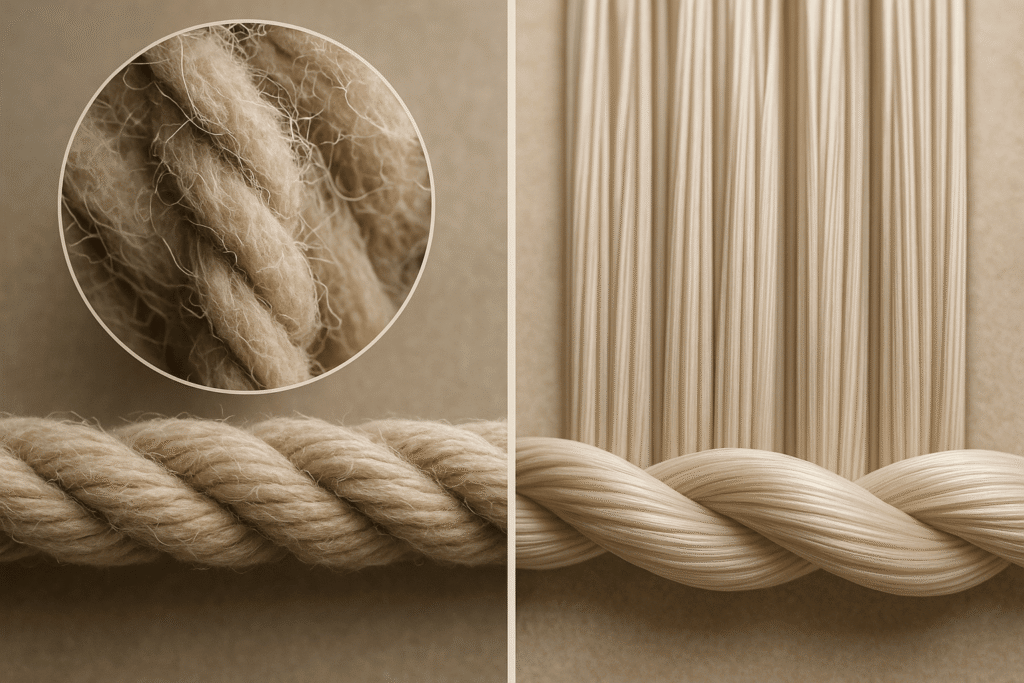

Spun yarns are made by twisting short fibers together to form a continuous thread, creating a textured, versatile yarn.

- Fiber Sources – Derived from natural fibers like cotton or wool, or synthetic staples like polyester, cut to short lengths for spinning into yarn.

- Twisting Process – Fibers are carded, aligned, and twisted, producing a yarn with a slightly fuzzy surface and flexible structure for various uses.

- Common Examples – Cotton knitting yarn, wool sweater yarn, and blended yarns used in everyday clothing or home textiles across markets.

- Tactile Appeal – Spun yarns feel soft and warm, making them ideal for cozy garments or absorbent towels, popular in Pakistan’s textile industry.

- Production Scale – Widely produced by yarn suppliers, spun yarns support both local crafts and large-scale textile manufacturing.

What Defines Filament Yarns?

Filament yarns are made from long, continuous strands, often synthetic, resulting in a smooth, strong thread.

- Continuous Fibers – Formed from long filaments, like silk from silkworms or synthetics like nylon, extruded as single, unbroken strands.

- Smooth Texture – Lack the fuzziness of spun yarns, offering a sleek, glossy finish that reflects light for a polished look in fabrics.

- Synthetic Dominance – Often made from polyester or rayon, filament yarns are engineered for specific traits like strength or sheen in modern textiles.

- Durability Factor – Their continuous nature makes them stronger than spun yarns, resisting fraying in high-wear applications like upholstery.

- Industrial Use – Filament yarns are key in Pakistan’s fabric production, supplied by fabric suppliers in Pakistan for dresses and technical textiles.

Spun yarns wrap you in warmth; filament yarns glide with elegance—both are textile magic.

Key Differences in Structure and Texture

Spun and filament yarns differ fundamentally in how they’re made, affecting their feel and performance.

- Fiber Length – Spun yarns use short, staple fibers twisted together, while filament yarns rely on long, continuous strands for a smoother finish.

- Surface Feel – Spun yarns have a fuzzy, soft texture, ideal for comfort, whereas filament yarns are sleek, with a slippery, polished surface.

- Strength Comparison – Filament yarns are stronger due to their unbroken structure, while spun yarns may wear faster but offer more flexibility.

- Visual Appeal – Spun yarns give a matte, cozy look, while filament yarns create shiny, refined fabrics for formal or decorative uses.

- Production Needs – Spun yarns require more processing steps, while filament yarns are simpler to produce, impacting costs for manufacturers.

Comparing Spun and Filament Yarns

|

Feature |

Spun Yarn |

Filament Yarn |

| Fiber Type | Short, staple fibers (cotton, wool) | Long, continuous filaments (silk, polyester) |

| Texture | Fuzzy, soft, matte | Smooth, glossy, sleek |

| Strength | Moderate, prone to pilling | High, resists fraying |

| Breathability | Good, airy structure | Varies, often less breathable |

| Common Uses | Sweaters, towels, casual wear | Dresses, upholstery, technical textiles |

| Maintenance | Washable, may shrink | Easy to clean, durable |

| Cost | Moderate, varies by fiber | Often cheaper for synthetics |

Best Uses for Spun Yarns

Spun yarns shine in projects where comfort and texture are priorities, making them a staple in many textiles.

- Casual Clothing – Cotton spun yarns create breathable T-shirts, jeans, and shalwar kameez, perfect for Pakistan’s warm climate.

- Home Textiles – Wool or cotton spun yarns form absorbent towels, cozy blankets, and soft bed sheets for everyday comfort.

- Crafting Projects – Knitters and crocheters love spun yarns for scarves and hats, as their fuzzy texture adds warmth and charm.

- Cultural Textiles – In Pakistan, spun yarns are used in traditional embroidery, adding softness to intricate designs for local markets.

- Affordable Options – Yarn suppliers offer spun yarns in various weights, catering to both artisans and industrial producers.

Top Applications for Filament Yarns

Filament yarns excel in projects needing strength, smoothness, or a polished look, often seen in specialized textiles.

- Formal Wear – Silk or polyester filament yarns create flowing dresses, suits, and sarees with a glossy, elegant finish for special occasions.

- Upholstery – Durable filament yarns like nylon form strong, sleek fabrics for furniture, resisting wear in high-traffic settings.

- Technical Textiles – Filament yarns make sturdy ropes, nets, and medical textiles, valued for their strength in demanding applications.

- Industrial Fabrics – Pakistan’s fabric suppliers use filament yarns for conveyor belts and geotextiles, supporting infrastructure projects.

- Shiny Aesthetics – Their glossy surface enhances decorative items like curtains or tablecloths, adding a refined touch to interiors.

Spun and Filament Yarns in Pakistan’s Textile Industry

Pakistan’s textile sector, a global powerhouse, relies on both spun and filament yarns to meet diverse demands.

- Export Market – Spun cotton yarns dominate clothing exports, while filament yarns like polyester fuel technical textile production for global trade.

- Local Crafts – Artisans use spun yarns for traditional weaves, while filament yarns add modern flair to Pakistan’s fashion industry.

- Production Hubs – Cities like Faisalabad and Karachi house yarn suppliers, providing both yarn types for local and international markets.

- Economic Impact – The yarn trade supports millions of jobs, from spinning mills to fabric weaving, driving Pakistan’s economy forward.

- Sustainable Trends – Suppliers are adopting eco-friendly spun and filament yarns, like recycled polyester, to meet global sustainability goals.

In Pakistan, yarns don’t just make fabric—they weave the story of our economy and culture.

Environmental Impact of Spun and Filament Yarns

Both yarn types have ecological pros and cons, influencing choices for sustainable textile production.

- Spun Yarns – Natural spun yarns like cotton are biodegradable but require water-intensive farming, though organic options reduce pesticide use.

- Filament Yarns – Synthetic filaments like polyester are non-biodegradable, contributing to microplastic pollution, but recycled versions help mitigate this.

- Energy Use – Spun yarns need more processing energy due to twisting, while filament yarns are simpler but often petroleum-based.

- Recycling Potential – Both can be recycled, with Pakistan’s fabric suppliers offering sustainable yarns to lower environmental impact.

- Local Efforts – Pakistan’s textile industry is investing in greener practices, like water-efficient spinning and recycled filament production.

Choosing Yarn Suppliers in Pakistan

Selecting the right supplier ensures you get quality spun or filament yarns for your textile needs.

- Variety of Offerings – Look for suppliers with a range of spun (cotton, wool) and filament (polyester, silk) yarns in different weights and colors.

- Quality Assurance – Reliable yarn suppliers test yarns for consistency, ensuring strength and texture meet project requirements.

- Market Expertise – Suppliers familiar with Pakistan’s textile needs can recommend yarns for clothing, crafts, or industrial applications.

- Supply Reliability – Choose suppliers with strong logistics to deliver bulk orders on time, critical for manufacturers and artisans alike.

- Sustainability Focus – Opt for suppliers offering eco-friendly yarns, like organic cotton or recycled polyester, to align with global trends.

A great yarn supplier doesn’t just deliver thread—they fuel creativity and industry with every skein.

The Future of Spun and Filament Yarns

Yarn production is evolving, blending tradition with innovation to meet modern textile demands.

- Eco-Friendly Yarns – Organic spun yarns and recycled filament yarns are gaining traction, reducing environmental impact in Pakistan and beyond.

- Advanced Spinning – New technologies improve spun yarn uniformity and filament yarn strength, enhancing textile quality for diverse uses.

- Smart Textiles – Filament yarns are being engineered for conductive or heat-resistant properties, used in wearable tech and medical fabrics.

- Local Innovation – Pakistan’s textile sector is adopting sustainable practices, with suppliers investing in greener yarns to stay competitive globally.

- Market Growth – Rising demand for both yarn types drives opportunities for fabric supplier to expand into new markets.

Wrapping Up

Spun and filament yarns each bring something special to textiles—spun with its cozy, breathable charm and filament with its sleek, durable shine. From cotton sweaters to polyester dresses, their differences shape the fabrics we love and use daily. In Pakistan, where textiles are a cultural and economic cornerstone, yarn and fabric suppliers keep the industry thriving with quality materials. Whether you’re crafting a handmade gift or scaling up textile production, understanding these yarns helps you choose wisely. Ready to start your next project? Connect with a trusted supplier and let the right yarn weave your vision into reality!