In high-performance engineering, material purity is not just a preference it is a necessity. Titanium Grade 1 Sheets are renowned for their ultra-pure composition, exceptional corrosion resistance, and superior ductility. These qualities make them indispensable in industries that demand precision, durability, and reliability, including aerospace, chemical processing, marine engineering, and medical devices.

1. Understanding Titanium Grade 1

Titanium Grade 1 is the softest and most ductile among commercially pure titanium grades, yet it retains impressive strength and stability. Its ultra-pure composition typically includes:

-

Titanium: ~99%

-

Oxygen: ≤0.18%

-

Iron: ≤0.20%

-

Carbon: ≤0.10%

-

Nitrogen and Hydrogen: Minimal traces

This purity ensures that Titanium Grade 1 Sheets remain highly corrosion-resistant and suitable for forming into intricate shapes without compromising their structural integrity.

2. Exceptional Corrosion Resistance

One of the standout features of Titanium Grade 1 Sheets is their outstanding resistance to corrosion, particularly in acidic, chloride-rich, and oxidizing environments.

-

Chemical Industry: Ideal for processing tanks, piping, and heat exchangers exposed to strong acids.

-

Marine Applications: Performs exceptionally in seawater and desalination plants, preventing rust and degradation over time.

-

Medical Sector: Biocompatible and resistant to bodily fluids, making it suitable for implants and surgical equipment.

This durability ensures long-term performance and minimal maintenance, reducing overall operational costs.

3. Lightweight Yet Durable

Titanium’s strength-to-weight ratio is one of its most valuable attributes. Titanium Grade 1 Sheets are lightweight yet maintain sufficient tensile strength for most industrial applications.

This lightweight property is critical in aerospace and automotive sectors, where reducing material weight improves fuel efficiency and performance without compromising structural safety.

4. Fabrication and Formability

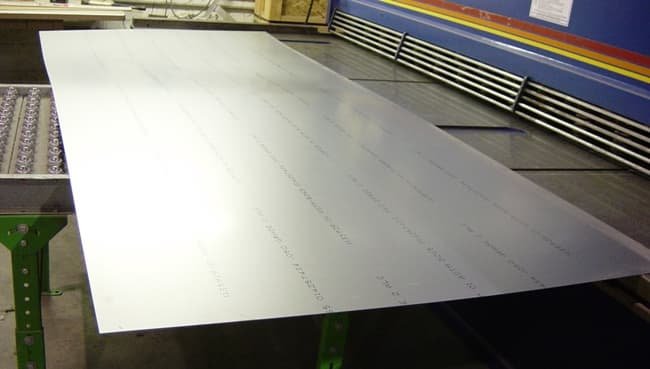

The softness and ductility of Titanium Grade 1 make it highly workable. These sheets can be easily cut, rolled, welded, and formed into precise components while maintaining corrosion resistance.

Engineers and manufacturers benefit from the ease of fabrication, allowing for complex designs and customized solutions across industries.

5. Key Industrial Applications

The versatility of Titanium Grade 1 Sheets allows them to be used in a wide array of applications:

-

Aerospace: Aircraft structural components, ducting, and heat shields.

-

Marine: Piping, tanks, and fasteners in corrosive seawater environments.

-

Chemical Processing: Reactors, heat exchangers, and acid storage systems.

-

Medical Devices: Surgical instruments, implants, and prosthetics.

-

Energy Sector: Components exposed to high-temperature and corrosive atmospheres in power plants.

Their consistent performance in harsh conditions makes Titanium Grade 1 Sheets a material of choice for engineers seeking reliability and precision.

6. Benefits of Using Titanium Grade 1 Sheets

-

Ultra-Pure Composition: Ensures consistent performance and resistance to corrosion.

-

Formability and Ductility: Easy to fabricate into precise components.

-

Biocompatibility: Safe for medical and food industry applications.

-

Long-Term Durability: Minimizes maintenance and replacement costs.

-

Lightweight Strength: Enhances efficiency in aerospace and marine applications.

These benefits make Titanium Grade 1 Sheets a strategic investment for industries aiming for efficiency, reliability, and longevity.

7. Sustainability and Environmental Impact

Titanium is not only durable but also environmentally friendly. Its long service life reduces the need for frequent replacements, and the material is fully recyclable, supporting sustainable engineering practices.

Industries focused on minimizing environmental impact benefit from using Titanium Grade 1 Sheets, aligning high-performance engineering with eco-conscious solutions.

Conclusion

From chemical processing to aerospace engineering, Titanium Grade 1 Sheets demonstrate how ultra-pure metals can deliver precision, durability, and corrosion resistance. Their combination of lightweight strength, formability, and long-term reliability makes them a top choice for critical applications across industries.

For engineers and designers seeking materials that can endure harsh environments while maintaining performance and efficiency, Titanium Grade 1 Sheets provide the ideal solution—proving that material purity is key to achieving superior engineering outcomes.